The Precision Engineering Workshop

The main focus of the precision engineering workshop is on the construction of prototypes for scientific applications. Together with the scientific staff, we develop devices and experimental setups – from the initial idea to the finished product. In addition, the workshop is responsible for repair and maintenance work. The team includes master precision engineers, technicians, skilled workers and apprentices.

The range of activities covers complex technical planning and design of customer-specific individual solutions using CAD/CAM systems, operational manufacturing processes with conventional drilling, turning and milling machines, and 5-axis simultaneous milling. For additive manufacturing, the precision mechanics workshop has various 3D printers at its disposal. Small welding jobs can also be carried out using the TIG (tungsten inert gas welding), MAG (metal active gas welding) or electrode welding processes. A laser cutter for cutting and engraving various materials has also been in use since the end of 2022. Likewise, the workshop team assists scientists in creating a wide variety of setups by selecting the appropriate materials in terms of stability and functionality.

CNC production of precision components

A central component of the precision mechanics workshop is a 5-axis CNC milling machine as well as two 3-axis CNC milling machines, one of which can be equipped with an additional fourth rotary axis. The maximum component size can be up to 1000 millimeters per workpiece. Even high-quality precision parts with the smallest shape and position tolerances can be produced. Depending on the material requirements, the most commonly used materials in CNC manufacturing are thermoplastics, various aluminum alloys and high-performance plastics such as PEEK, as well as various copper alloys and stainless steels.

Additive manufacturing using 3D printers

Additive manufacturing is a process in which computer-aided design can be used to create three-dimensional workpieces using appropriate 3D printers. With the existing FDM and SLA printing processes, a broad spectrum can thus be developed. At the institute, this manufacturing technology is particularly suitable for the production of brackets, molds, disposable electrode drives, and coilformers used in on-site MRIs.

Likewise, the workshop team supports the scientists in creating the individual measurement setup on site, by choosing the appropriate installation site in terms of necessary infrastructure and existing interferences. On the basis of various tests, suggestions are made to the scientist as to how the setup can be jointly created with suitable shielding in a neutral room.

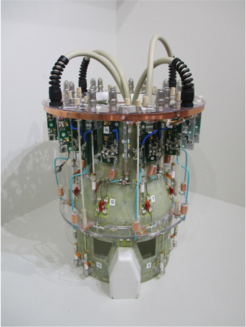

Work example: development and manufacture of a head coil

Head coils ensure excellent imaging capabilities for neurological studies. They can be used in standing, sitting and lying positions. For the development and manufacture of a head coil that is used for experiments with strong magnets on human subjects, most of the development and manufacturing processes are handled in-house. The coils are specially designed in terms of weight, shape and material properties for strong MRI magnets up to 14 T.